|

|

It usually takes the Sugar Maple more than 40 years to grow larger than

12 inches in diameter at chest height. At that time, it is ready for

one tap. Near the end of February, when alternating freezing and

thawing temperatures generally begin, sugarmakers make the rounds of

their "sugarwoods", drilling 1 cm (7/16") holes about 5 cm (2-2 1/2")

into the trunk of the tree.

Depending on the tree's diameter and strength, it may be fitted with as

many as three (3) taps. Trees with trunks less than 25 cm in diameter

should not be tapped at all. Prudent tapping is harmless to the maple -

many trees have been tapped continuously for more than 150 years. Metal

or plastic spouts are inserted, and buckets are hung, or plastic tubing

is connected from tree to tree.

From mid-march to the beginning of April, alternate freezing and

thawing changes the pressure inside the tree and starts the sap flowing

with the weather growing warmer, and temperatures rising above the

freezing level. At this point, the clear, slightly sweet liquid will

begin to drip into the buckets or through the network of tubing.

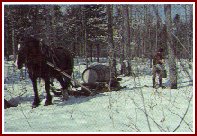

Traditionally, after the sap was collected in troughs, it was emptied

into a large barrel carried on a horse-driven sleigh.

In the mid-1970's, this technique was gradually replaced by a tubing

system, in which a partial vacuum is maintained using a pump. This

method of collection, which does not damage the trees, yields more sap

and reduces the manpower required and allows the producer to tap more

trees, including those located in rugged terrain.

When a pipeline system is used, the sap flows directly downhill through

the tubing to a central collection point. The sap will stop "running"

when temperatures fall below freezing, and run again when it rises. It

is a general rule-of-thumb that each tap will yield 10 gallons of sap

throughout an approximate six week season, producing 1 quart of maple

syrup.

In several maple sugaring operations, the maple syrup production

process is the same, but the equipment has changed. Taps, or spigots,

are made of metal. Buckets are aluminum or plastic. Buckets have lids

to keep the sap clean, free from snow, bark, and twigs. Sap is gathered

by walking from tree to tree only in traditional Sugar Bushes.

In modern, more efficient Sugar Bushes, elaborate tree-to-tree pipe

systems are used to run the sap directly into the Sugar Camp.

If

It's

Not From The Forest, It's Not

Wild!

Mike Poulin,

|

|

|